Submitted by: Susan Marshall, Electro technics Corporation (ELTEC) and Mike Grenert, Whelen Engineering, contributing author.

Rectangular Rapid Flashing Bea-cons approved by the FHWA for uncontrolled pedestrian crossings are a ‘hot’ product within the traf-fic industry. In January of this year, the FHWA clarified that the LED indications in RRFB’s must meet the SAE J595 Class 1 light intensity of 200 candela (cd). A compliant RRFB indication can no longer “meet the minimum specifications of Society of Automotive Engineers (SAE) standard J595” as originally stated in the July 16, 2008 memo. What does that really mean? What other factors affect the quality of a RRFB signal/indication?

There are three Classes under SAE J595: Class 3 is certified at 20 cd’s (candela) and used for identification only on vehicles such as forklifts, people carts in airports, etc. Class 2 is certified at 50 cd’s and used pri-marily with maintenance or service vehicles. Class 1 is certified at 200 cd’s and is used by police, fire and ambulance vehicles for signaling motorist to yield right of way.

A candela is the rating of light out-put at the source. In simple terms, 1 candle at 1 foot = a candela. The RRFB indications that were used to test the effectiveness of ‘motorist yielding to pedestrians’ in St. Pe-tersburg, FL were Class 1. In com-parison, a Class 3 indication is only visible for approximately 50 feet in daylight where a Class 1 indication is visible up to 1000 feet (and up to 1 mile at night).

The Class 1 light intensity contrib-utes to the effectiveness of motorist to “yield to pedestrians” (high 80% and close to 100%) compared to standard flashing beacons (15%-20%).

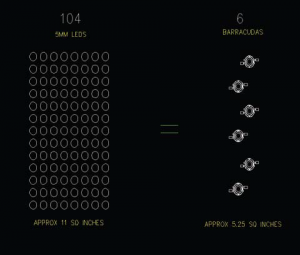

Does size of the LED indication mat-ter? In other words, does the sur-face area of the indication determine light intensity? Is bigger better or brighter? The July ‘08 FHWA memo specified “each RRFB indication shall be a minimum of approximate-ly 5 inches wide by approximately 2 inches high.” The fact is that the surface area of the indication does not determine the level of bright-ness. The light output of the LED and photometric qualities of the reflector and lens determines how many LED’s must be used to pro-vide the required Class 1 light level. Some RRFB indications contain only 6 LED’s to meets the Class 1 light intensity requirements.

Even if a signal contains numerous LED’s, it still may not have the 200 candela intensity required by the FHWA. Why is that?

There are several types of light emit-ting diodes used in the manufactur-ing of the indications, and technol-ogy continues to improve the qual-ity. For example, one Luxeon style of diode, developed in 2000 has the same light intensity as eighteen (18) 5mm diodes developed in the ’80’s. Six (6) Luxeon diodes housed in a RRFB indication produces approxi-mately the same light intensity as 104 55mm diodes!

LED’s produce less light and re-duce their life expectancy as their operating temperature increases. Therefore, a lower quality diode driven harder burns hotter resulting in reduced light output and a short-ened life compared with a higher quality diode, which is properly driven. A good quality diode has a life expectancy of approximately 100,000 hours. As it concerns the RRFB, manufacturers usually offer a five (5) year warranty on each indication.

There are inherent losses with any LED fixture design. All of the light produced by the LED must be ef-fectively controlled to optimize efficiency. LED fixture output val-ues can vary dramatically. As light travels through the lens, reflection and refraction may cause it to lose intensity. The lens clarity and mate-rial used affect the visible light.

Other factors affect the light inten-sity. In addition to the type of diode, the reflector used to distribute light output affects signal intensity. The style of the reflector used in combi-nation with the diode in the RRFB indication determines how the light is spread.

Knowing how the light is dispersed may be beneficial with some instal-lation settings (hospitals, neighbor-hoods, etc). There are two types of designs that dispense light: focused and wide angle. Light emitted in a ‘cone’ shape is fairly focused: not wide up/down or left/right. The light widens with distance. Like a flash light, the ‘cone’ style reflector focuses the light making the beam more intense up close; it spreads out as it’s aimed farther. A linear design gives a wider angle of light. You lose some of the direct light in-tensity because of the light spread. Both types are classified in the Class 1 features.

All these things coming together create the overall photometric qualities of the indication: the LED; reflector; and lens & refractor system. The efficiency of the diode and the engineering of the design to the complete indication determines the quality and intensity of the light emitted. To confirm if the RRFB indications meet the FHWA Class 1 requirement, request a copy of a lab certificate.

Bottom line, as outlined in the origi-nal FHWA memo the “data clearly documents very successful and impressive positive experience with the RRFB’s at crosswalks….”